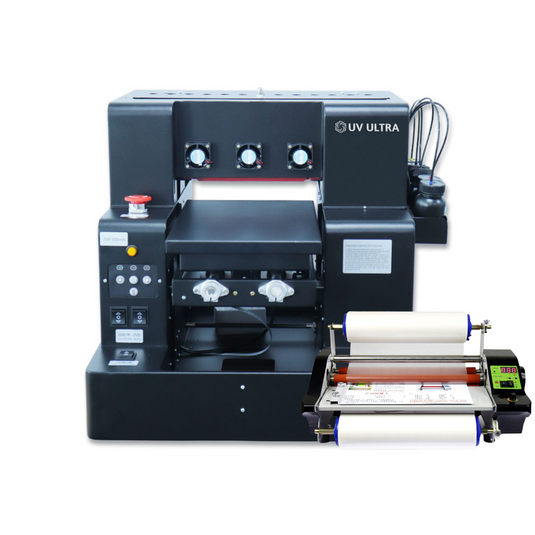

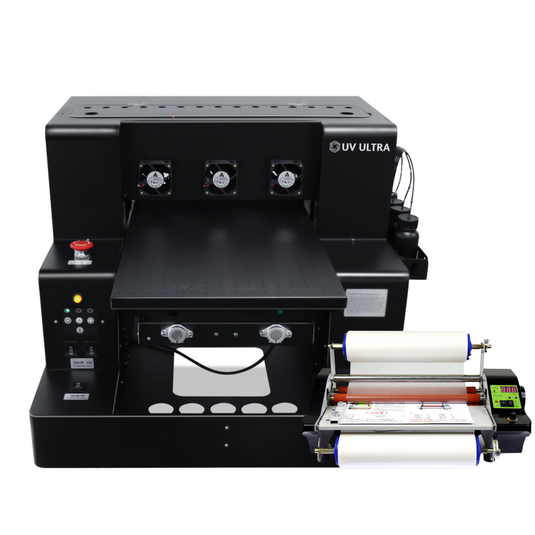

UV DTF Printers

UV DTF printers offer you a game-changing way to apply graphic designs to a vast range of products, materials, and objects and level up the look and appeal of your merchandise. Instead of being restricted to certain shapes, sizes, and surfaces, you have free reign to create crystal stickers for application onto just about anything. Our machines use industry-grade UV ink to ensure optimal color saturation that gives you long-lasting results. Each printer is sold as part of a comprehensive bundle, including all necessary consumables, so you have everything you need to get started immediately.

FAQs

What objects can you print onto using a UV DTF printer?

You can use our machines to print on a variety of materials including glass, plate, crystal, ceramics, wood, PVC, acrylic, metal, plastic, stone, and leather, among others. Create graphic design stickers for almost any flat or cylindrical surface, including wooden or metal plaques, tiles, phone cases, bottles, cans, glasses, wallets, belts, and more.

Is a UV DTF printer better than a DTF printer?

UV DTF machines use advanced technology to give you high-resolution prints that last a long time. They create stickers that are designed for use on hard surfaces, such as plastic, wood, metal, glass, ceramics, and others — but not fabrics. Standard DTF printers, on the other hand, create design films that can be heat transferred onto many different fabrics.

How is a UV DTF Printer different from a standard UV printer?

Standard UV printers print directly onto the object, such as phone cases, pens, ceramic tiles, wallets, or USB dongles, to name a few. However, you’re limited by the size of the object; For example, the A4 L805 UV has a maximum printing height of 150mm, so the flatbed product would need to be within 150mm in height or thickness.

UV DTF printers let you create stickers that you can use to transfer your design onto different objects. You’re not limited by size and can apply designs on irregularly-shaped or very large objects, since you only have to peel the sticker and place it where you want.